Custom Refractory Solutions | Your Trusted OEM Partner

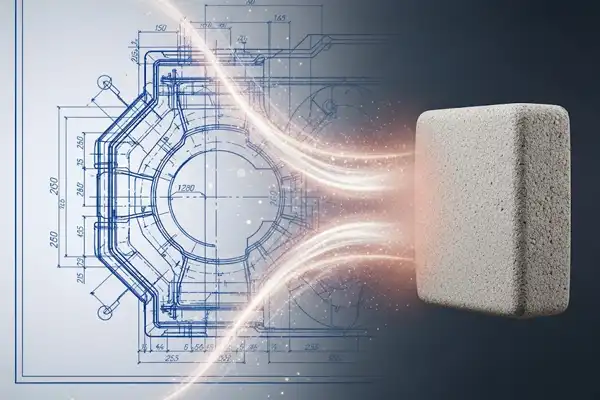

As a leading refractory manufacturer, we offer comprehensive OEM services including custom formulation, R&D, and quality-controlled production. Partner with us to bring your unique refractory designs to life. Fast, reliable, and tailored to your exact needs.

Our Refractory OEM Service Types

In extremely high temperature and harsh application environments, the performance of refractory materials directly determines the service life and production efficiency of equipment. Our “Refractory Formulation Development and Optimization Service” aims to provide you with customized formulations that go beyond conventional solutions to help your products and equipment meet the most severe challenges.

General-purpose refractories often fail to address the corrosion, wear, thermal shock, or chemical attack challenges found in specific operating conditions, shortening equipment life and reducing production efficiency.

Our refractory application solutions service provides one-stop, customized solutions from diagnosis and design to implementation.

Refractory OEM customization process

Demand Communication and Project Analysis

First, we conduct in-depth discussions with our clients to fully understand their specific refractory needs, including application conditions, technical specifications, and project drawings. This serves as the foundation for providing you with a professional, customized solution.

Technical Evaluation and Design

Our engineers will professionally evaluate your drawings and data and design the optimal refractory solution, including material selection and structural design. After consultation, we will confirm the details of the custom refractory material.

Formula Development and Sample Production

Based on the design proposal, we will develop a custom formula. Once the refractory formula is developed, we will conduct a small-batch trial production, with quality control throughout the entire trial production process.

Sample Testing and Customer Confirmation

After the sample is produced, we conduct rigorous testing, including every indicator in the custom requirements document. We strictly record the test data and submit all test results to our customers to confirm that the sample performance meets their requirements.

Mass Production and Process Quality Control

Once the customer confirms the sample's performance, we begin mass production, strictly adhering to the established process. We monitor quality at every stage of refractory production to ensure that all products meet the contracted standards.

Logistics Delivery and After-Sales Support

Once the product is complete, we will carefully package it and arrange logistics to ensure safe and timely delivery. We also provide ongoing after-sales technical support to address any issues our customers may encounter while using our refractory materials.

FAQs when OEM customized refractory materials

What types of refractory materials can you customize?

How long does the customization process typically take?

The specific timeframe depends on the complexity of the project. Generally speaking, the entire process, from initial requirements discussion and drawing review to sample production and final mass production, can take anywhere from four to twelve weeks. We will provide a detailed project timeline.

How do you ensure the quality of your custom products?

We have a strict quality control system. From raw material procurement to final product delivery, every step is rigorously tested. We provide comprehensive performance test reports to ensure our products meet your technical requirements and industry standards.

What is the minimum order quantity (MOQ)?

The MOQ depends on the type and complexity of your custom product. For some specialized products, we often have minimum production batch requirements. Please contact us with your specific requirements and we will provide you with a detailed quote.

If I don't have a complete drawing, but only an idea or concept, can you help?

Of course. Our experienced R&D team can work with you to transform your concept into a viable technical drawing and formula. We provide one-stop support from design, development, and production.

Will you protect my designs and business secrets?

We sign strict nondisclosure agreements (NDAs) with all OEM customers. Your designs, formula information, and business data will be protected at the highest level.

What if a product problem occurs after mass production?

We provide comprehensive after-sales technical support. If a product experiences any issues during normal use, we will investigate and provide solutions to ensure your project remains unaffected.

How is the price for custom services determined?

The price is determined by the material type, design complexity, production volume, and specific performance requirements. After a full assessment of your needs, we will provide a detailed and transparent quotation.

How do you protect my design if it involves a patent or proprietary technology?

We place the utmost importance on intellectual property protection. Before starting a project, we are committed to signing a strict Non-Disclosure Agreement (NDA) with all clients to ensure your designs and trade secrets are fully and permanently protected.

Can you accommodate small-batch or prototype orders?

Yes, we can handle small-batch and prototype orders. This is crucial for R&D projects, as it allows you to thoroughly test and validate the material’s performance before committing to large-scale production.

Can you provide independent third-party test reports?

Yes, in addition to our rigorous in-house quality control, we can arrange for independent third-party testing from certified laboratories. This provides objective and impartial performance data for your custom products, building trust.

Have Anything To Ask Us?

Please fill in your email in the form and we’ll get back to assist you soon!