Refractory quality control: attention to detail

We make an unwavering commitment to quality for every refractory product we make. Our quality control is more than just a process; it’s a solemn response to our customers’ trust. This page details how we use precise component analysis, rigorous performance testing, and a comprehensive quality traceability system to ensure that every product you receive delivers stable and reliable performance under the most demanding operating conditions, creating lasting value for you.

Our quality control process

Inspection of incoming refractory raw materials

All raw materials (such as high-purity bauxite, aluminum oxide, and clay) undergo rigorous chemical composition analysis and physical property testing before entering our warehouse. We only accept materials that meet our pre-set standards, eliminating substandard products at the source.

Ingredient precision control

We use an advanced automated batching system to precisely control the weight and proportion of each raw material. This precision is essential to ensure consistent and stable final product performance.

Molding Process Monitoring

Whether it’s pressing refractory bricks or drawing ceramic fibers, we monitor pressure, density, and molding temperature in real time. This determines the structural density and strength of the product.

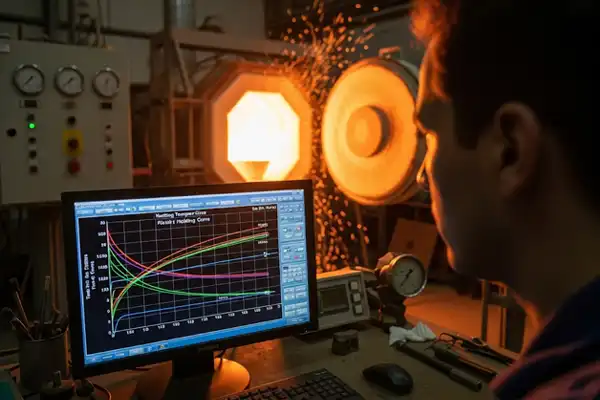

Firing Temperature Curve Control

During the kiln sintering process, we strictly control the heating, holding, and cooling curves. Precise temperature control is critical to ensuring the refractory bricks are fully sintered and achieve the desired crystal structure and physical properties.

Finished Product Physical Property Testing

Before each batch of products leaves the factory, comprehensive physical property testing is performed, including bulk density, apparent porosity, room-temperature compressive strength, and refraction under load. These data directly reflect the product’s durability and load-bearing capacity.

Finished Product Dimensions and Appearance Inspection

We use professional measuring tools to rigorously inspect the size, shape, and appearance of each product. This ensures accurate dimensions, free of cracks, chipping, and other defects, ensuring easy installation.

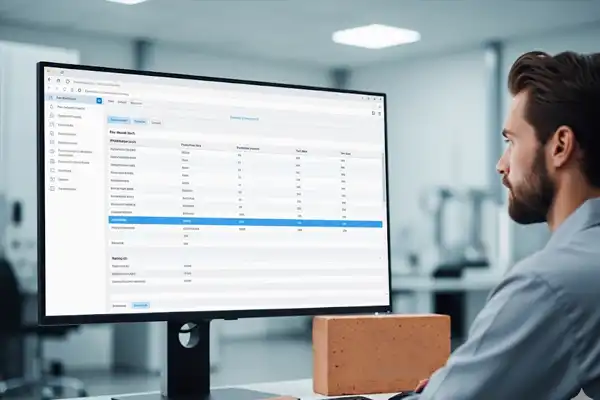

Quality Traceability System

We maintain independent quality traceability records for each batch of products. From raw material batches, production dates, production parameters, to test data, all information is readily available, enabling full process traceability and rapid response and resolution of any customer issues.

Packaging and Shipping Control

Before shipping, we use sturdy packaging to protect your products from moisture and damage during long-distance transportation. We oversee the packing process and record shipping details to ensure your shipment arrives safely and intact.

The above 8 quality control links effectively ensure that our refractory materials can perfectly adapt to the needs of customers in different environments. But obviously, our quality control of refractory products goes far beyond this. If you want to know more details or want to customize refractory materials with special properties, please contact us.

Have Anything To Ask Us?

Please fill in your email in the form and we’ll get back to assist you soon!